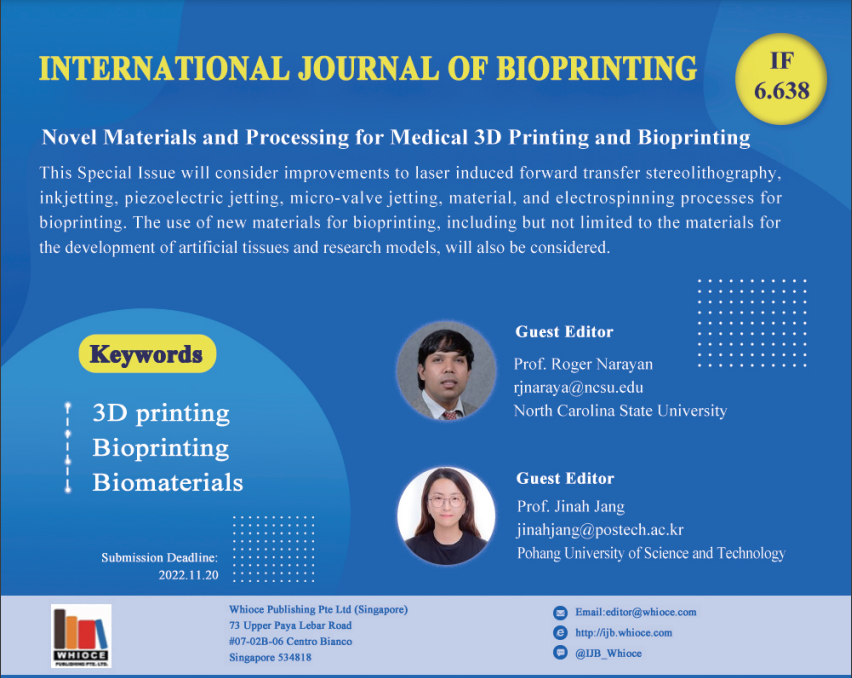

Over the past two decades, the inclusion of biological materials such as drugs, cells, growth factors, and peptides as part of the feedstock materials for additive manufacturing has grown. The aim of this special topic is to publish a collection of papers on Novel Materials and Processing for Medical 3D Printing and Bioprinting. The issue will consider improvements to laser induced forward transfer stereolithography, inkjetting, piezoelectric jetting, micro-valve jetting, material, and electrospinning processes for bioprinting. The use of new materials for bioprinting, including but not limited to the materials for the development of artificial tissues and research models, will also be considered.

Fabrication of large-scale scaffolds with microscale features using light sheet stereolithography

A novel photocurable pullulan-based bioink for digital light processing 3D printing

Extrusion Printed Silk Fibroin Scaffolds with Post-mineralized Calcium Phosphate as a Bone Structural Material

A Review on Bioinks and their Application in Plant Bioprinting

Development of P(3HB-co-3HHx) nanohydroxyapatite (nHA) composites for scaffolds manufacturing by means of fused deposition modeling