Artificial Intelligence is being used more and more for the analysis of the datasets that are produced from the Additive Manufacturing Process. These data sets include IR, acoustic, eddy current, oxygen, composition and part density data. Often fundamental models can be produced which predict the melt pool width and height, the part density, pore formation, thermal fields, resulting microstructure, and part mechanical properties. While these analytical and FEA models can give a good understanding of the process. However, in many situations they are too slow for real time quality or close loop process control. Surrogate models (also called metamodels) are commonly being used instead for these predictions where faster analysis is required. Where the analytical and FEA models are validated within defined bounds, they can be used to generate a lot of process input and output simulation data. This data can be used in conjunction with the experimental data to train the AI models and thereby make them available for more real time process quality prediction or control.

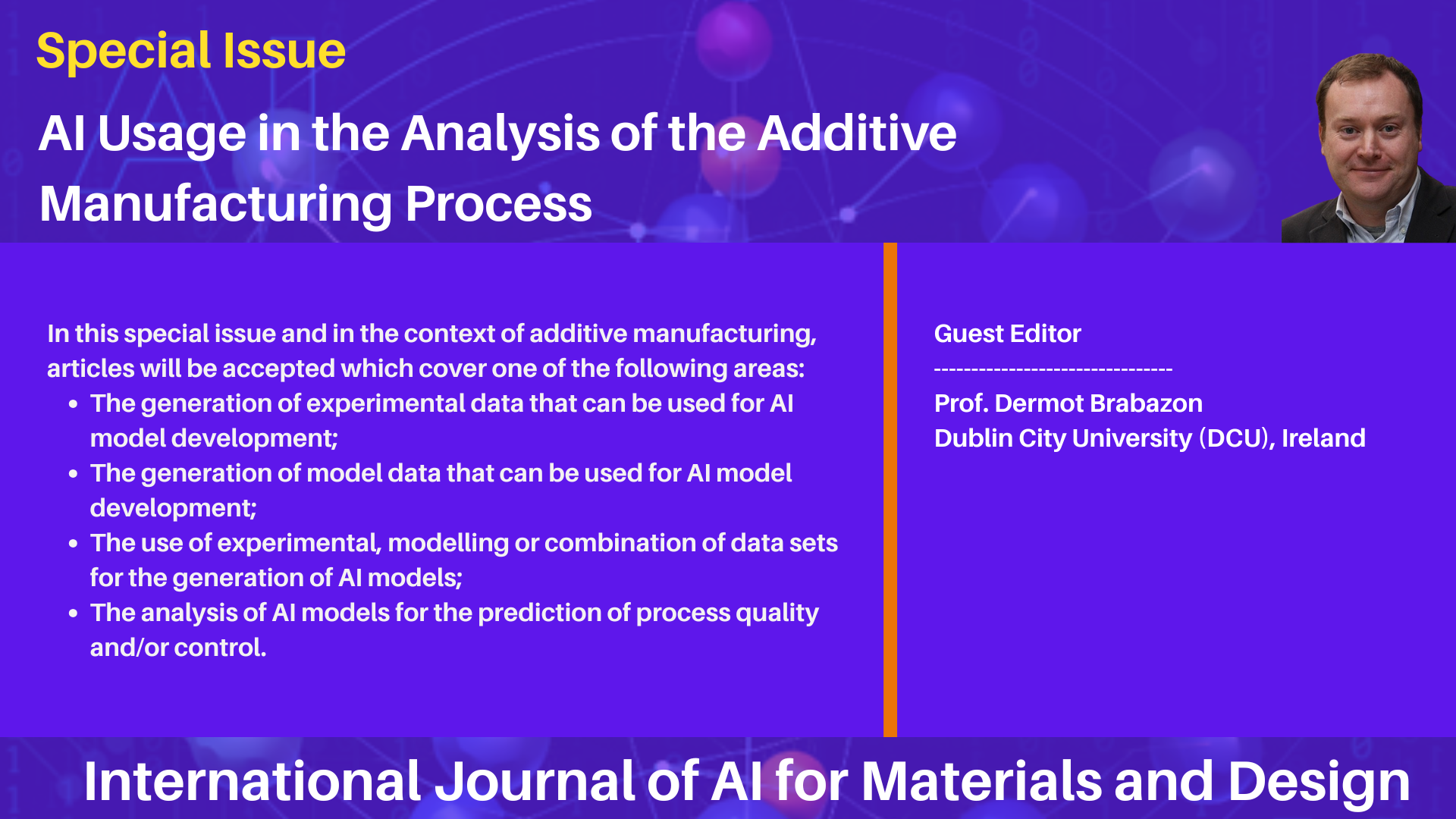

Original research articles and reviews that fall within this topic area are welcomed. In this special issue and in the context of additive manufacturing, articles will be accepted which cover one of the following areas:

- the generation of experimental data that can be used for AI model development;

- the generation of model data that can be used for AI model development;

- the use of experimental, modelling or combination of data sets for the generation of AI models;

- the analysis of AI models for the prediction of process quality and/or control.

Prediction of wall geometry for cold-metal-transfer-based wire-arc additive manufacturing

Layer porosity in powder-bed fusion prediction using regression machine learning models and time-series features

A data-efficient machine learning approach for amorphous Fe-based bulk metallic glass fabrication in powder bed fusion