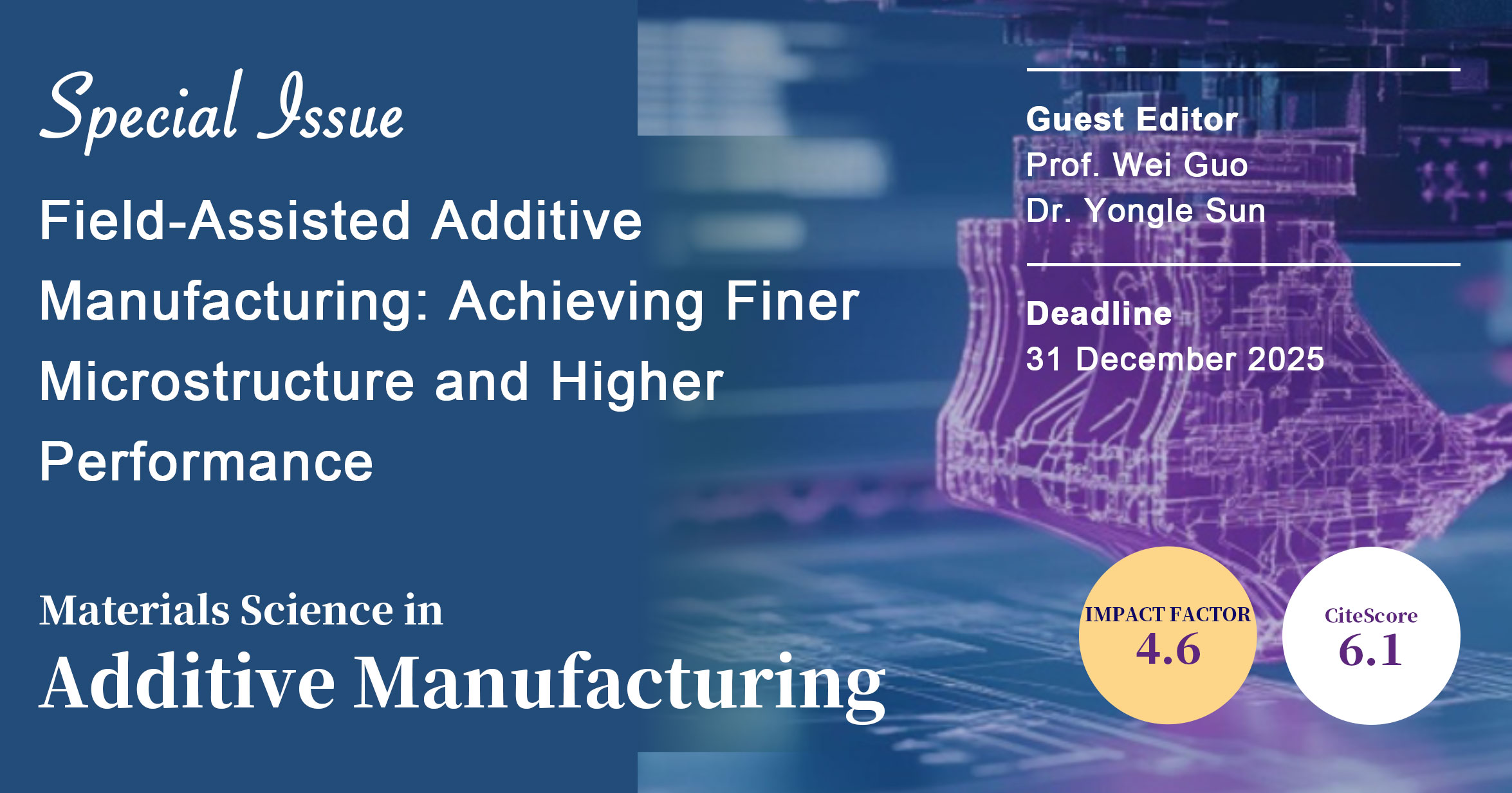

Additive manufacturing (AM) has been recognized as one of the top ten disruptive technologies that enable the fourth industrial revolution. It offers unprecedented design freedom and manufacturing flexibility for fabrication of complex components. However, there are still some bottlenecks hindering the wide-scale industrial adoption of AM techniques. Defects in poor-printability materials result in poor fatigue performance; large columnar grain structures result in anisotropic and unfavorable mechanical properties; residual stress results in poor structural integrity, etc. To tackle these challenges, novel methodology has been developed for a solution by integrating different AM technologies with auxiliary field, such as thermal, magnetic, electric, acoustic and mechanical fields. The auxiliary fields can significantly affect the molten pool convection and dynamics, alter the thermal cycles during material solidification and induce stress or plastic deformation to the AM built components. The scope of this special issue includes but is not limited to field-assisted additive manufacturing from perspectives of materials, methodologies, and applications.