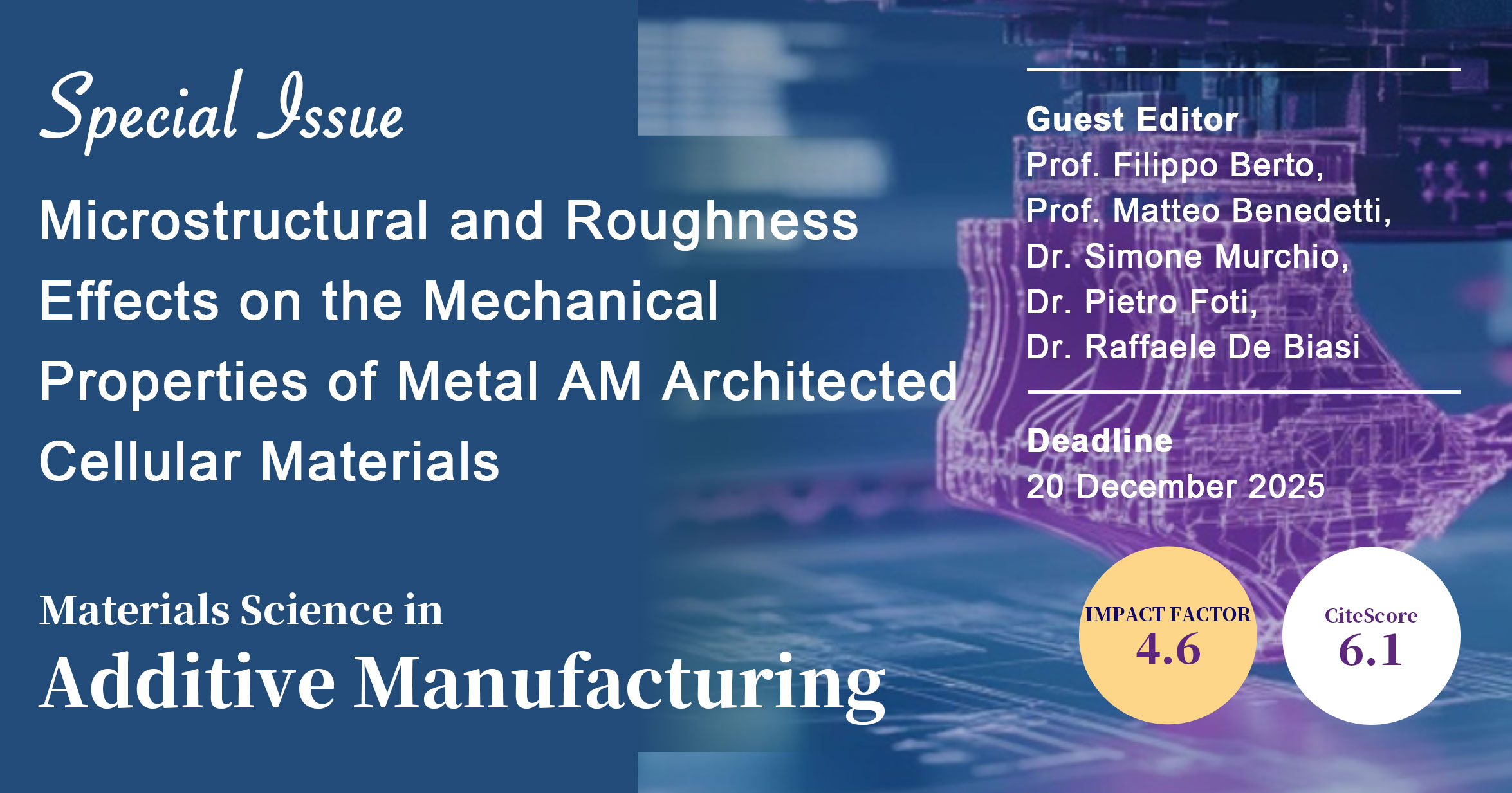

Microstructural and Roughness Effects on the Mechanical Properties of Metal AM Architected Cellular Materials

Metal Additive manufacturing (MAM) enables the design and fabrication of architected cellular materials with tailored mechanical performance. However, the intrinsic microstructural heterogeneity and surface roughness introduced by MAM processes pose significant challenges in predicting and optimizing their mechanical behavior. This Special Issue aims to gather high-quality research focused on understanding how microstructural features (e.g., grain morphology, grain boundaries) and process-induced defects (e.g., surface roughness, internal defects) influence the mechanical properties of architected cellular structures produced by AM. Contributions that explore experimental characterization, computational modeling, multiscale analysis, and process-structure-property relationships are particularly welcome. Emphasis will be placed on studies addressing fatigue, fracture, deformation mechanisms, and structural integrity, paving the way toward performance-driven design of MAM lattice-based components.