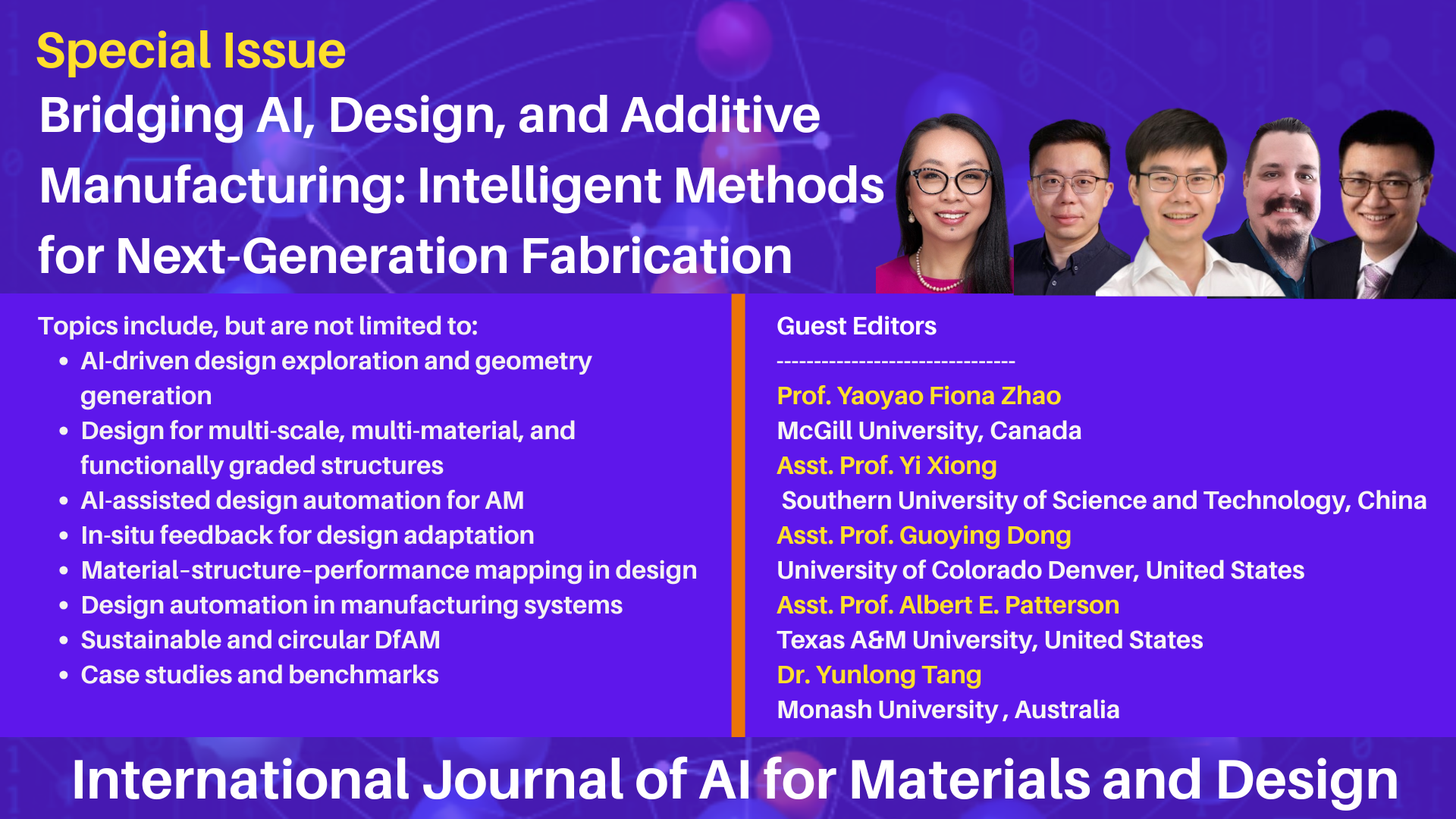

Bridging AI, Design, and Additive Manufacturing: Intelligent Methods for Next-Generation Fabrication

Additive manufacturing (AM), also referred to as 3D printing, has matured into a powerful suite of technologies enabling the fabrication of complex geometries, multi-material composition, and highly customized products. However, achieving robust, efficient, and high-fidelity outcomes remains challenging due to the complex interactions among process parameters, material behaviors, geometrical design, and post-processing operations. Artificial intelligence (AI) techniques—including machine learning, data-driven modeling, optimization, generative design, and hybrid physics-informed approaches—offer powerful means to accelerate and enhance the additive manufacturing ecosystem. By integrating AI into the design loop, AM can achieve higher levels of automation, adaptability, and performance. AI enables the creation of manufacturable and high-performance geometries, dynamic optimization of process parameters, and real-time monitoring with feedback control. It also allows for more accurate prediction of material behavior and performance, supports multi-material and functionally graded designs, and embeds digital twins and physics-guided models into the design–manufacturing workflow.

This special issue aims to bring together cutting-edge research at the intersection of AI, computational design, and additive manufacturing. We invite contributions exploring both methodological advances and real-world applications. We welcome high-quality original research articles, review papers, and application/industry case studies. Topics include, but are not limited to:

- AI-driven design exploration and geometry generation: generative design, topology optimization, and AM feature-informed design methods that link design intent with manufacturability and performance.

- Design for multi-scale, multi-material, and functionally graded structures: AI-guided modeling and optimization of hierarchical and heterogeneous geometries.

- AI-assisted design automation for AM: data-driven and hybrid models connecting design parameters, process settings, and resulting quality or properties to inform early-stage design decisions.

- In-situ feedback for design adaptation: using sensing, monitoring, and digital twins to connect process data back to design models for real-time or iterative redesign.

- Material–structure–performance mapping in design: prediction and optimization of microstructure, stresses, and performance outcomes to guide design refinement.

- Design automation in manufacturing systems: AI-enabled path planning, scheduling, and hybrid (additive–subtractive) strategies that preserve design intent through production.

- Sustainable and circular DfAM: AI-supported design methods for minimizing material use, enabling repair/reuse, and optimizing lifecycle performance.

- Case studies and benchmarks: demonstrations of AI-enhanced DfAM methodologies, open datasets, and validation frameworks that support reproducible design research.

Artificial intelligence and additive manufacturing as a coupled design system: Rethinking inference, manufacturability, and design education